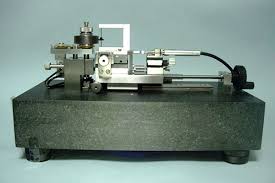

Gear Double Flank Tester

The Gear Double Flank Tester is a precision metrology system used to evaluate the composite quality of gears by measuring transmission error and variation under loaded conditions. This method is essential for identifying imperfections such as pitch errors, profile deviations, and eccentricity. Using a reference master gear, the tester rotates the test gear in mesh, capturing real-time rolling characteristics across the full flank width.

Key Features

- Double Flank Rolling Test: Measures total composite variation between a master gear and the test gear with constant center distance.

- Non-Destructive Inspection: Ideal for final quality checks without damaging the gear.

- High Sensitivity Gauging System: Detects minute variations in center distance or angular motion.

- Digital Data Capture: Interface with SPC software for real-time analysis, storage, and quality reporting.

- Adaptable Fixtures: Accommodates a wide range of gear sizes and profiles, including spur and helical gears.

Measurable Parameters

- Total Composite Error (TCE)

- Tooth-to-Tooth Variation (TTTV)

- Runout or Eccentricity

- Backlash (indirectly, by analyzing error patterns)

- Noise Signature (optional with acoustic/vibration modules)

Applications

- Automotive: Transmission gears, differential components, e-mobility systems

- Aerospace: Precision actuation gears, auxiliary drive gears

- Industrial: Robotics, gearboxes, precision machinery

- Quality Control Labs: Routine inspection, batch validation, and R&D

Benefits

- Comprehensive Gear Quality Insight: Evaluates total gear performance, not just individual geometrical parameters.

- Efficient Testing: Quick setup and test cycles allow high-throughput inspections.

- High Repeatability: Rigid construction and precision components ensure reliable results across multiple tests and operators.

- Versatile Use: Suitable for production line testing, quality audits, or engineering analysis.

Optional Features

- Motorized Drive Unit with Speed Control

- Noise & Vibration Analysis Kit

- Automatic Master Gear Change System

- Temperature Compensation Module

- Custom Fixtures for Non-Standard Gear Forms